.png)

Lehigh & Hudson River Railway Snow Flanger #105 Restoration Update

Story by John Boner

March 2021

March 2021

What is a flanger?

A snow flanger is a specialized type of railroad car designed to clear snow and ice from between the rails on a track. This area is called the flangeway, where the flanges of the wheels go, to keep the car on the rails. To do this it has a heavy angled blade under the car that is notched, so that part of it fits inside the rails while another part rides on top of them. The car usually has an enclosed body that can be heated for the crew that operate it and any additional workers who may ride along to shovel out when needed. The operator must have good visibility so that he can raise the blade when approaching switches. The car is towed by a locomotive, rather than pushed like a plow.

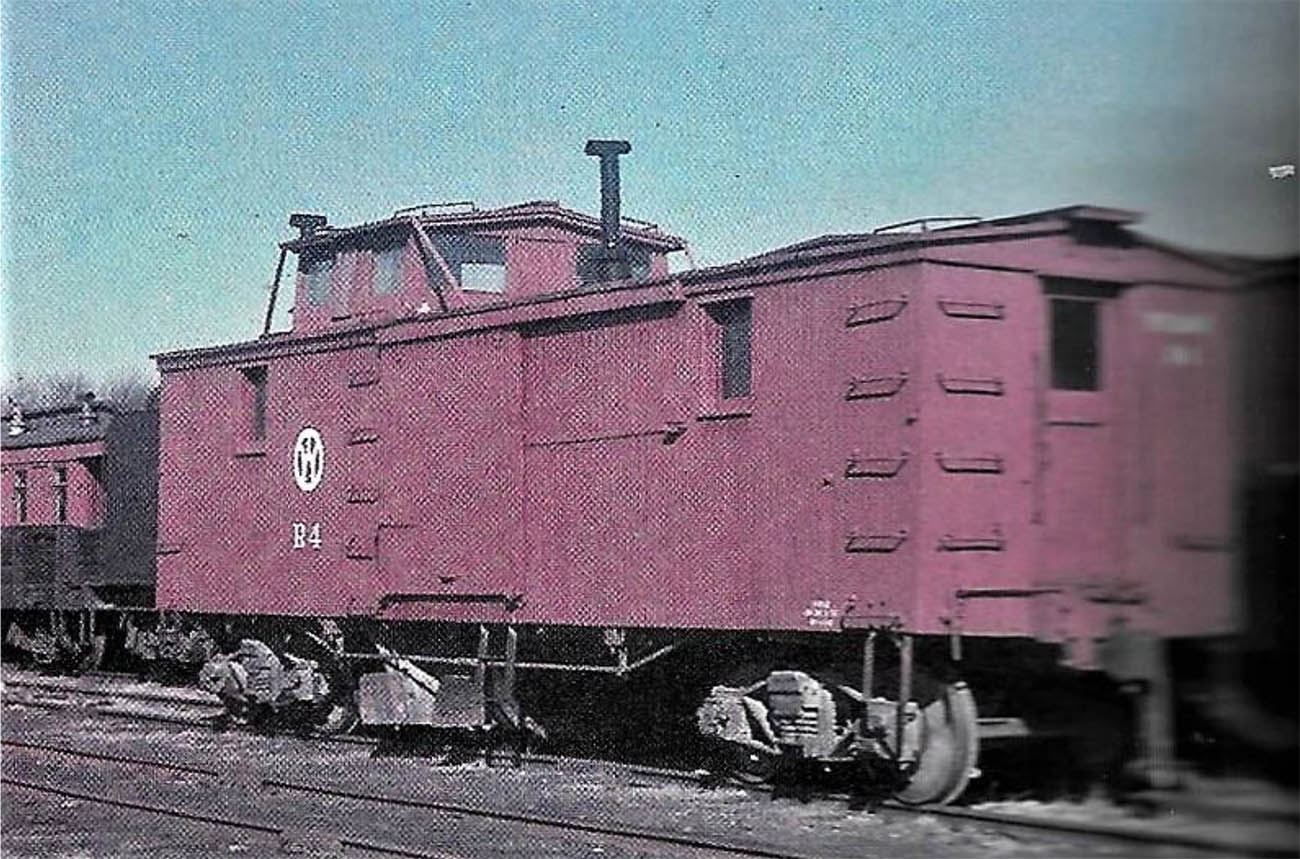

L&HR #105 in Warwick NY. 1968 - Houser Photo

The flanger has 2 blades for clearing snow, so that it will operate in either direction on the rail line without needing to be turned.

The plow blades in this picture are in the up position allowing them to clear switches and grade crossings. Pete Blaess photo.

A Brief History of Our Flanger

Our flanger was originally built as either a boxcar or milk car. We do not have a definite build date but the construction technique places its origin sometime in the 1870's to 1880's. The boxcar was converted in 1913 by the New York, Ontario & Western Railroad which operated in areas of very heavy snowfall in upstate New York, and was one of several such home-built flangers, constructed using obsolete boxcars.

Our flanger in Middletown, NY still wearing New York and Ontario and Western #4 livery. Date unknown. From the Pete Delikat collection

The plowing apparatus appears to have been home-built, using sheet steel and parts of regular air-brake mechanisms - the blades were air-operated, with two large reservoirs at one end of the car. The original 37' boxcar was apparently stretched to accommodate the plowing mechanism, and a cupola was added for the operator (possibly taken from an old caboose). As the N.Y.O.&W. declined, various pieces of equipment were sold-off, and our flanger passed into the hands of the Lehigh & Hudson River Railway in 1957. It is unclear if the L&HR ever used it. When wooden cabooses and crew cars were outlawed in the 1950's, the car, along with all of the LHRR cabooses were placed in storage at the railroad's Warwick, N.Y. yard for some years.

This 1974 photo shows the 105 in the Warwick NY dead line. Paul Carpenito photo.

Some time, in the 1960's apparently, a number of the cars stored in Warwick were moved to the former Ingersoll-Rand property in Phillipsburg, N.J. where they lingered outside for years, subject to weather damage and vandalism. The cars were abandoned on the property and, as operations at the plant wound down, the company donated them to our museum, along with one of their plant locomotives.

The flanger on the Ingersoll plant railroad in 1990. From the PRRH collection.

In 1991 the cars were moved to our first site near the Delaware River Park. The flanger got a new coat of paint. The wooden cupola was rotting so it was removed. Atlantic States Pipe foundry offered to have their wood shop fabricate new cupola parts using the old rotting parts as a template. In 1998 our cars were moved from the brickyard to our present site off South Main Street.

PRRH founding president Pete Terp stands in front of the flanger and the last I/R Phillipsburg plant switcher after being moved to the old brickyard property in 1991. The flanger cupola wood frame was rotting so it was removed. From the PRRH collection.

After our collection was moved to our current site some work was done on the flanger, but the work stopped, and the car was placed in storage under a large tarpaulin. We have wanted to continue work on this car for years, but other, more pressing needs took the time of our volunteer workers away from the project. In 2004, three of our members Pat Graham, Earle Brotzman, and John Boner built a new "false roof" to protect the car from the weather.

In the summer of 2004 Pat Graham (on ladder), Bud Sauselein (standing) and Earle Brotzman work on shoring up the original roof prior to fabricating the temporary roof. From the PRRH collection.

Pat Graham (l) and John Boner (r) nail down the temporary plywood roof. From the PRRH collection.

Restoration Begins

The temporary roof worked very well for about 10 years, but by 2018 it was beginning to decay. We had just completed rebuilding of LHRR caboose #18 at this time, and two members, Pete Delikat and John Boner decided to tackle the flanger project. In April of 2018 the flanger was moved into the carshop. The car is remarkably well preserved, inside and out - with the exception of the cupola, which had been removed, and it is hoped to preserve most of the original materials. Much research was done before starting this project, and we have learned even more as we began the restoration.

The first order of business in 2018 was to remove the temporary roof and assess the condition of the car. John Boner photo.

Work continued in 2019 to determine how much of the original car could be saved. The top sill, some of the side slats and some floor boards were removed due to rotting wood. Early in 2020 Covid put a stop to most work on the PRRH site. Later in 2020 we were devastated by the passing of Pete Delikat, but two other members, Carl Pierson and Ed Ott have joined the crew and the project continues.

In December 2020 when temperatures and conditions allowed, we worked on getting scaffolding set up for work on the roof. This involved re-siting and partially rebuilding the cantilever structure used for caboose #18, along with added reinforcement, and also erecting some of our commercial scaffolding to work on the opposite side of the car.

The cantilever is getting an upgrade. Horizontal 2 X 8 boards are attached to the wall timbers, a platform is then constructed on the cantilevered boards. This is used in place of scaffolding for working on the upper parts of the south facing car exterior thus allowing freedom of movement on the shop floor where clearances are tight. John Boner photo.

Sheets of plywood were placed over the roof supports to provide a working platform while repairs were made to some cross-pieces. John Boner photo.

After the repairs were made work began on fitting pieces for a new side top-sill. Rotted sections of the old sill were removed, some steel braces had to be disconnected, and new sections fitted. At the same time, some of our workers set-in one of the prefabricated cupola end sections for a test-fitting, and to determine just how to attach them. John Boner photo.

Unfortunately, extremely heavy snows throughout February of 2021 temporarily isolated the shop, and made it impossible to continue the work, but we look forward to starting up again in March.